STM32 Nucleo

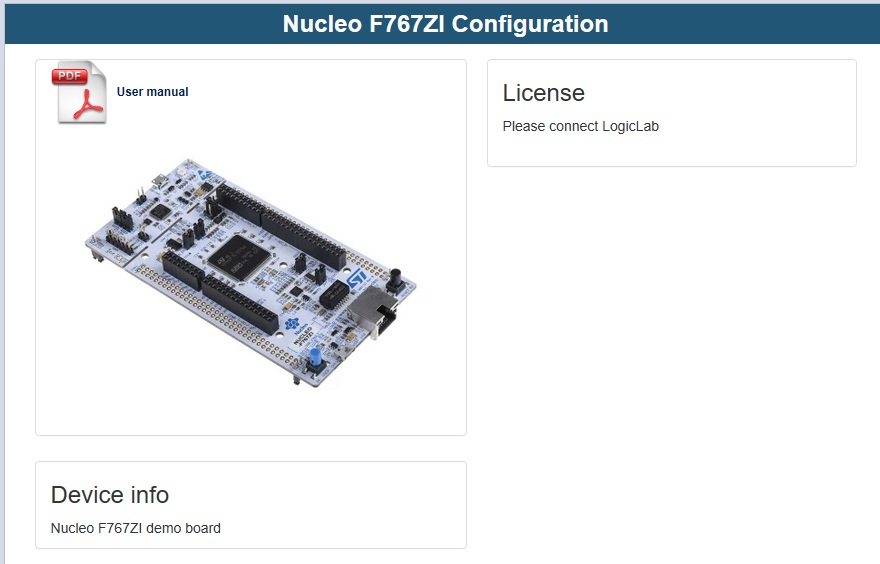

STM32 Nucleo F767ZI demo board can be used with LogicLab Automation Suite.

All informations about Nucleo F767ZI target board and ST software are available on STMicroelectronics website [1]

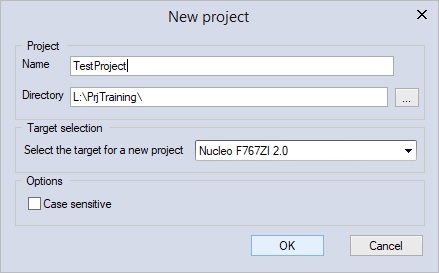

How to start

1) Download Axel Automation Suite

2) Install Axel Automation Suite

3) Start LogicLab and create new Nucleo project

4) From the main target page open user manual

5) See user manual chapter 3 - Firmware Upgrade to configure Nucleo target board with Axel Nucleo firmware

6) See user manual chapter 1 - Quickstart to connect to target device via USB-Serial or Ehernet

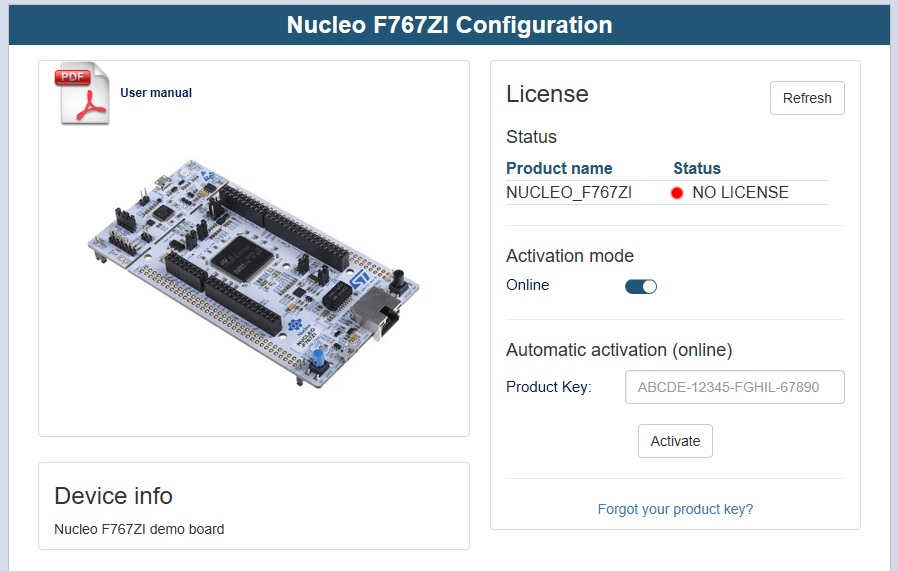

7) Once connected to target, enter product key provided by Axel in main target page

8) Nucleo is now ready for LogicLab

User plugins and firmware development

Nucleo firmware source can be provided by Axel only by explicit request.

If request is accepted Axel will provide firmware sources and guidelines for development.

Nucleo firmware has been developed using STM32CubeIDE.

See Nucleo versions for the STM32CubeIDE version used for development.

Nucleo versions

Nucleo F767ZI 3p0

- PLC

- SoftScope

- Database

- Local I/O (plugin sample)

- Modbus RTU master

- Modbus RTU slave

- CANopen master

- Modbus TCP master (new)

- Modbus TCP slave

- Symbols server (new)

- Network scan support

- Plugin API for custom plugins development

- Plugin builder (new)

Firmware developed and tested with STM32CubeIDE 1.5.1

Nucleo F767ZI 2p0

- PLC

- SoftScope (new)

- Database

- Local I/O (plugin sample)

- Modbus RTU master

- Modbus RTU slave

- CANopen master

- Modbus TCP slave (new)

- Network scan support (new)

- Plugin API for custom plugins development (new)

Quickstart and documentation Nucleo_F767ZI_2p0.pdf

Firmware developed and tested with STM32CubeIDE 1.3.0

Nucleo F767ZI 1p0

- PLC

- Database

- Local I/O

- Modbus RTU master

- Modbus RTU slave

- CANopen master

- Modbus TCP slave

Quickstart and documentation Nucleo_F767ZI_1p0.pdf

Firmware developed and tested with STM32CubeIDE 1.3.0

Nucleo F767ZI firmware

Based on Nucleo F767ZI 3p0 firwmare

| Plugin/sw component | Is plugin | Flash | RAM | Description | Notes |

|---|---|---|---|---|---|

| AlPlcRuntimeCore & porting | No | 50 KB | 48 KB | Validate, manage and run PLC code | Includes math, real, string and time plugins, functions to manage system events, download and storage |

| PLC code | No | 512 KB | - - - - - | Reserved area for PLC application code | Code is run directly from flash |

| PLC data | No | - - - - - | 128 KB | Reserved area for PLC application variables | |

| Database | No | 16 KB | 1 KB + (***) | Manage persistency and access to system and application parameters | Requires reserved flash sectors for parameters values storage (**) |

| Modbus TCP slave | No | 12 KB | 16 KB | Allow a client to access database parameters via Modbus TCP | Requires LwIP stack |

| Network scan | No | 1 KB | 4 KB | Manage UDP requests for target recognition | |

| FreeRTOS + HAL drivers + LwIP stack + other | No | 164 KB | 72 KB | FreeRTOS real time O.S., low level drivers, TCP/IP stack, main, wrappers | Required for Modbus TCP slave, Network scan, Modbus TCP master |

| SoftScope | Yes | 7 KB | 16 KB | Real time oscilloscope plugin | 8KB of data required for data transfer in real time mode (acquisitions of 8 tracks at 1 ms) |

| Local I/O | Yes | 1 KB | 1 KB | Basic I/O plugin | |

| Modbus RTU master + slave | Yes | 17 KB | 65 KB + (*) | Modbus RTU master + slave stack | Configured to manage up to 32 slaves |

| CANopen master | Yes | 18 KB | 2 KB + (*) | CANopen master stack | Can manage up to 126 slaves |

| Modbus TCP master | Yes | 18 KB | 26 KB + (*) | Modbus TCP master stack | Configured to manage up to 16 slaves. Requires LwIP stack |

| Symbols server | Yes | 46 KB | 1 KB + (*) | Allow access to PLC symbols from clients that uses LLSymbols.dll | Symbols table is allocated into PLC code area |

| Total size (No PLC areas) | 350 KB | 263 KB | Fimware occupation NOT including PLC code and data reserved area | ||

| Total size | 862 KB | 391 KB | Fimware occupation including PLC code and data reserved area | 512 KB for PLC code, 128 KB for PLC data |

(*) some resources, depending on user configuration, are allocated into PLC data area when plugin configuration code is generated.

(**) database manager can be configured to save parameters into file systems or EEPROM if available

(***) 2 KB for parameters and status variables datablocks